With the ability to create custom objects quickly and efficiently, 3D printing has opened up a world of possibilities for designers and engineers. But what if we could take 3D printing a step further? What if we could use AI and other tools to make the process even more efficient and streamlined?

In a world where every company is looking for more efficient ways to manufacture, AI has become an essential tool for product design and manufacturing. By harnessing the power of AI, companies can improve their processes and production rates, resulting in higher quality products. AI is already being used across many industries today. In manufacturing, it can help improve product design and manufacturing by automatically creating 3D models, optimizing production processes, streamlining operations and helping to find the optimal design outcomes. Designers need to consider various factors such as functionality, aesthetics, cost, and sustainability. How can they find the best solutions among countless alternatives?

Generative Design: A Game Changer for Product Design and Materials Selection

One tool that can help them in this process is generative design software. Generative design software is a form of artificial intelligence (AI) that can generate and evaluate multiple design options simultaneously. It works by taking a set of design goals and constraints as input, and then using algorithms to explore the design space and find the most suitable solutions. The software can also provide feedback and suggestions to improve the design.

Generative design software can offer several benefits for product design and materials selection. First, it can help designers create more efficient and effective products that meet the desired specifications and performance criteria. For example, generative design software can optimize the shape and structure of a product to reduce its weight and increase its strength. Second, it can help designers reduce the amount of material and energy needed for production. By using generative design software, designers can create products that use less material or use more sustainable materials. This can lower the environmental impact and the cost of production. Third, it can help designers unleash their creativity and innovation. By using generative design software, designers can explore new possibilities and discover novel solutions that they might not have thought of otherwise. It can enable designers to create better products faster and cheaper, while also reducing their environmental footprint.

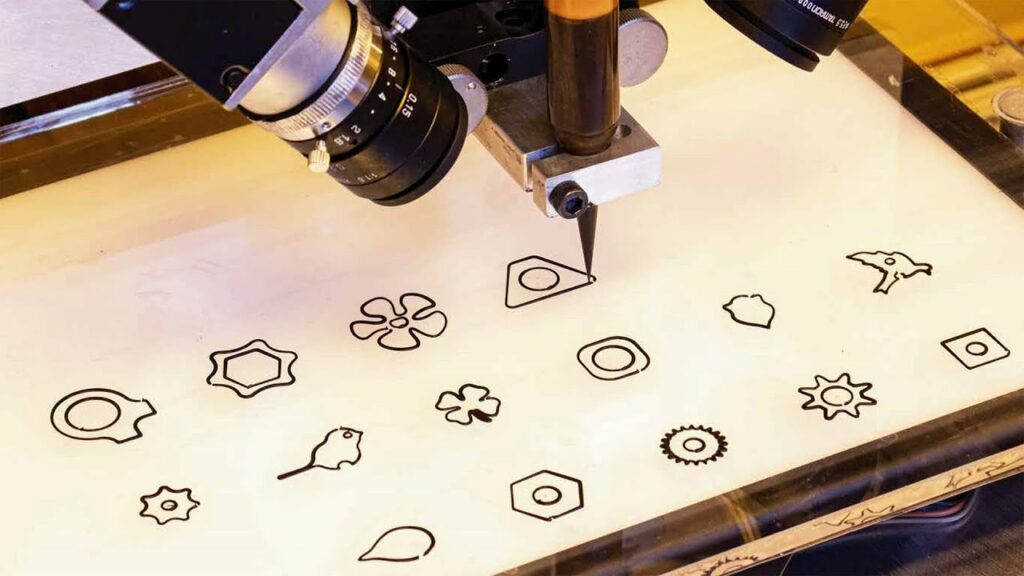

Generative Design Possibilities

Generative Design PossibilitiesMIT Researchers Develop AI System to Optimize 3D Printing Parameters

MIT researchers have developed an AI system that can automatically identify the optimal parameters for 3D printing several objects. The system works by analyzing a database of 3D printed objects and their corresponding parameters, such as the speed of the print head and the temperature of the printing material. It then uses machine learning algorithms to identify patterns and correlations between the parameters and the quality of the printed objects.

Once the AI system has learned these patterns, it can use them to generate optimized printing parameters for new objects. This could potentially save a lot of time and effort, as currently, finding the best printing parameters often involves a lot of trial and error.

The AI system is still in its early stages and has only been tested on a small number of objects. However, the researchers are optimistic about its potential to improve 3D printing in a variety of industries, from aerospace to medical devices.

Optimizing 3D Parameters with AI

Optimizing 3D Parameters with AI An Automated Pipeline for Designing Fluidic Devices

MIT researchers have also developed a computational pipeline that automatically designs fluidic devices. Before, such devices were designed, prototyped, and tested manually by experienced engineers, a labor-intensive and costly process. Users can specify the locations and speeds at which fluid enters and exits the device, and the pipeline generates an optimal design that meets their goals. Researchers developed a computational technique that overcomes the limitations of manual design processes, such as the necessity to specify a device’s shape in advance. With the new system, experts are able to create more complex shapes.

The researchers’ system uses 3D blocks that can vary their shape to smoothly generate a design for a fluidic diffuser that channels liquid from one large opening to 16 smaller openings. Image Credits: Yifei Li/MIT CSAIL

The researchers’ system uses 3D blocks that can vary their shape to smoothly generate a design for a fluidic diffuser that channels liquid from one large opening to 16 smaller openings. Image Credits: Yifei Li/MIT CSAILChat GPT as a Tool to automate the Design Process

OpenAI’s Chat GPT language model, which has been in the news a lot lately, can generate text-based descriptions of 3D models, automating the design process. Design professionals who need to create complex 3D models quickly and efficiently can benefit from this feature. The language model generates a detailed description of the 3D model based on a few basic parameters, such as the object’s size and shape. Designers save time and effort by not having to design and refine the 3D model manually. By automating this process, designers can concentrate on other aspects of the project, such as aesthetics and functionality.

From 2D Images to 3D models

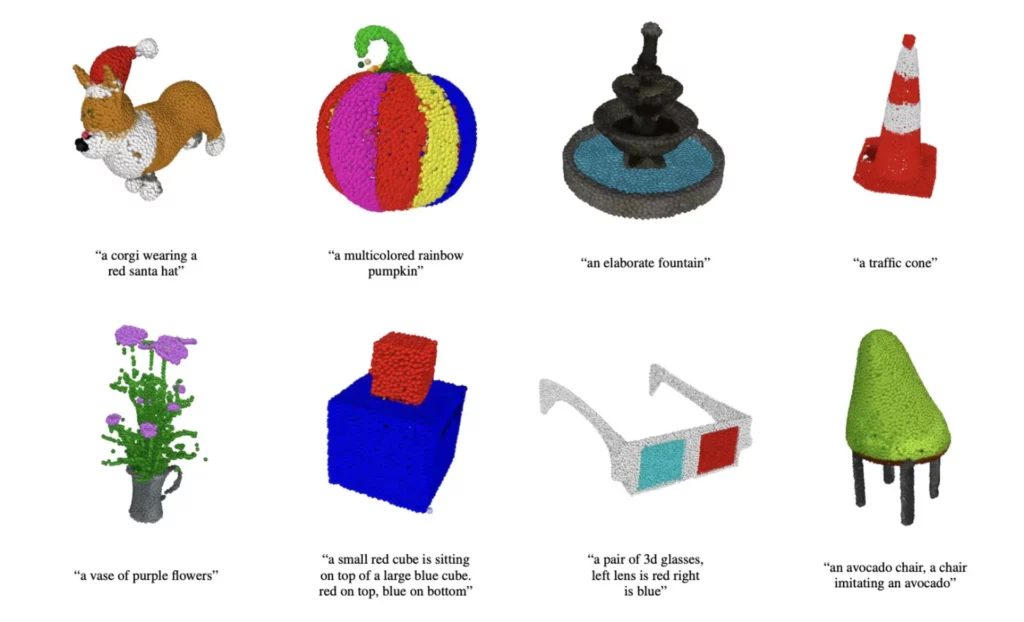

In addition, OpenAI has developed an AI-powered tool called Point·E that can create 3D models from 2D images in just a few minutes. This breakthrough technology uses a combination of computer vision and deep learning to accurately map the 2D images to 3D models.

Image Credits: OpenAI

Image Credits: OpenAIThe PointPainting model works by identifying key points in the 2D image, such as the corners of buildings or the edges of objects, and then using these points to generate a 3D model. This process is much faster and more accurate than traditional 3D modeling techniques, which can take hours or even days to complete.

One of the key advantages of PointPainting is its ability to generate highly detailed 3D models from just a few 2D images. This makes it ideal for applications such as virtual reality, video game development, and even architecture and engineering.

OpenAI has already released the PointPainting model as an open-source tool, making it freely available to developers and researchers around the world. This move is expected to accelerate the development of new applications and use cases for this exciting technology.

Image Credits: OpenAI

Image Credits: OpenAIThe PointPainting model is a significant leap forward in 3D modeling, and is likely to have a significant impact on many industries and applications in the future.

In addition to these tools, there are several other ways that AI can be used to enhance the 3D printing process. For example, AI can also be used to predict potential printing errors or defects, allowing designers to make corrections before printing.

Challenges of Integrating AI into 3D Printing: Data Scarcity and High Costs of AI Tools

Obviously, AI can offer many benefits for 3D printing. However, integrating AI into the 3D printing process is not without challenges. One of the main challenges is the data scarcity problem. In order to train AI algorithms to perform various tasks, such as generative design, quality control, or defect detection, large amounts of data are required. The data should be relevant, accurate, and diverse to ensure that the AI algorithms can learn from different scenarios and situations. However, obtaining such data can be difficult, especially for smaller companies or individual designers who may not have access to large databases or datasets. Moreover, the data may not be readily available or standardized for certain applications or domains. Therefore, data scarcity can limit the potential and performance of AI in 3D printing.

Another challenge is the high costs of AI tools and software. AI tools and software are essential for integrating AI into the 3D printing process. They enable designers and engineers to create, train, test, and deploy AI algorithms for various purposes. However, AI tools and software can be expensive to acquire and maintain. They may require specialized hardware, such as GPUs or cloud computing services, to run efficiently and effectively. They may also require licenses or subscriptions to access certain features or functionalities. These costs can be prohibitive for smaller companies or individual designers who may not have sufficient budgets or resources to invest in AI tools and software. Therefore, high costs of AI tools and software can hinder the adoption and integration of AI in 3D printing.

The Future of AI in 3D Printing: Enhanced Efficiency, Reduced Costs, and Innovative Applications

Despite these challenges, the potential benefits of using AI in 3D printing are too many to ignore. Designers can create more effective and efficient products by automating design, optimizing printing parameters, and predicting printing errors with AI, while also reducing production time and costs. 3D printing will continue to progress as AI technology advances, leading to even more innovative applications. AI can enable 3D printing to create more complex and customized products that are not possible with traditional manufacturing methods. AI can also enable 3D printing to create products that can adapt to changing environments or user preferences by using smart materials or sensors. Additionally, AI can enable 3D printing to create products that can interact with other devices or systems by using communication or networking technologies. These applications can have significant impacts on various industries and domains, such as healthcare, aerospace, automotive, education, entertainment, and more.