Our vision is to create a society that is regenerative by design, using natural materials at their highest value that enable a truly circular economy

Therefore we are developing a digital platform that helps you

to find the best sustainable material for your product.

Bioplastics: An Overview

Almost every conventional plastic can be replaced by a bioplastic and biobased does not always mean biodegradable

Benefits of Bioplastics

As a renewable, local resource, bioplastics tackling climate change and help to close the loop

Best Bioplastic Gift Ideas

See our best bioplastic gift ideas, do something good for your loved ones and our planet

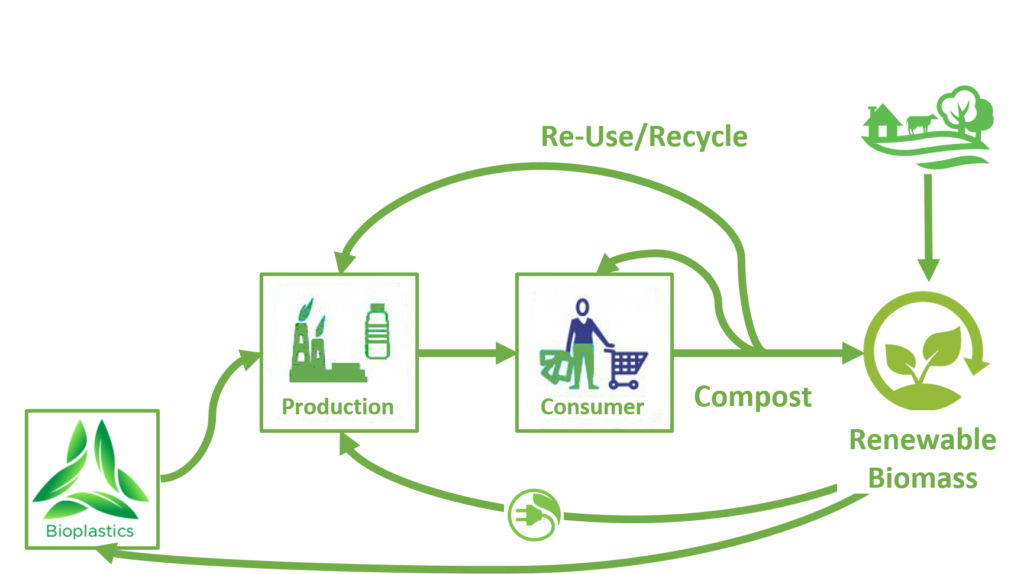

Bioplastics in a Circular Economy

Bioplastics

are made from biomass, such as green waste from a local farm, directly as a

material, or indirectly as energy. The other way around, biomass can be made

from degradable bioplastics and the circle continues.

85 % of every conventional plastic material can be replaced with a bioplastic alternative that decreases GHG emissions and accelerates the transition to a circular economy

Sources of Bioplastic

1. Generation

Vegetable Oils: soy, palm, sunflower, castor, rapeseed oil, etc.

Starch: corn, wheat, potatoes, tapioca, etc.

Glucose: sugar cane, beets, etc.

2. Generation

Biomass from Lignocellulose: wood, by-products or waste from agriculture or the timber industry (bagasse from sugar cane, straw, etc.)

Municipal Waste: organic waste, sewage, etc.

3. Generation

Microorganism: microalgae, bacteria, fungi, yeast, etc.

Bio-based polymers are made from renewable raw materials that are also used for other purposes, in particular for feeding humans and animals. The proportion used for the production of bioplastics, however, is marginal (approx. 0.02 of the global agricultural area). The bioplastics industry is also adopting the use of non-food crops (2nd and 3rd Generation), such as cellulose and algae or organic waste with a view to its further use to produce bioplastics materials. The even larger growth in the use of biomass feedstock for non-food purposes has demonstrated the technical possibility of producing these materials on a million-ton scale, substituting petrochemical plastics in meaningful quantities.

Material Properties and End of Live Options

Bio-based or partially bio-based durable plastics, such as bio-based or partially bio-based PE, PET, PP, PVC or biobased nylons, are called drop-in bioplastics and are technically equivalent to their fossil counterparts; yet, they help to reduce a product’s carbon footprint. These biobased versions can be recycled in the same way as traditional materials using the existing infrastructure and without affecting the quality of the recycled plastic.

New biomaterials, such as PLA, PHA, Cellulose or starch-based materials offer solutions with completely new funtionalities, such as compostability and in some cases optimised barrier properties. Along with the growth in variety of bioplastic materials, properties, such as flexibility, durability, printability, transperency, barrier, heat resistence, gloss and many more have been significantly enhanced.