One of the main reasons why bioplastics have not been adopted more yet, is that often they can’t compete on price with fossilbased materials (at least this goes for the traditional manufacturing technologies). That means they need to offer other benefits, let’s have a look into these benefits.

There are two major advantages of biobased plastic products compared to their conventional versions:

1. They save fossil resources by using biomass which regenerates (annually) and provides the unique potential of carbon neutrality or even carbon sink as they are capturing renewable carbon in the material throughout the entire product life span.

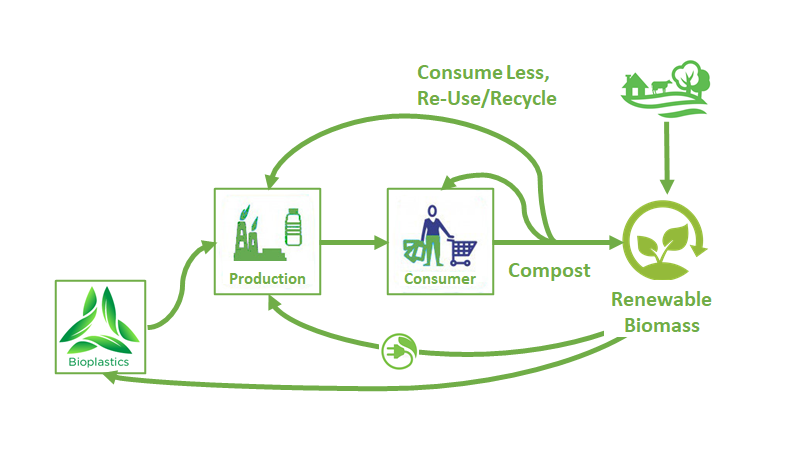

2. Biodegradability is an add-on property of certain types of bioplastics. It offers additional means of recovery at the end of a product’s life. Products can be organically recycled at the end of a product’s life cycle and create valuable biomass (humus) during the process. The humus can be used to grow new plants.

Bioplastics are Closing the Loop

Another huge benefit of biobased plastics is their possibility of using a local resource like plants or other kind of biomass (e.g. corn, crab shells, straws, hemp fibers etc…) for the production. This fits totally into the concept of 3d printing and the circular economy. Production material does not need to be shipped around the world anymore but plastics can be produced closer where consumption is. Furthermore, plastics that are bio-based and compostable can help to divert biowaste from landfill and increase waste management efficiency.

Bioplastics are made from biomass, such as green waste from a local farm, directly as a material, or indirectly as energy. The other way around, biomass can be made from degradable bioplastics even if it is contaminated with food and the circle continues.

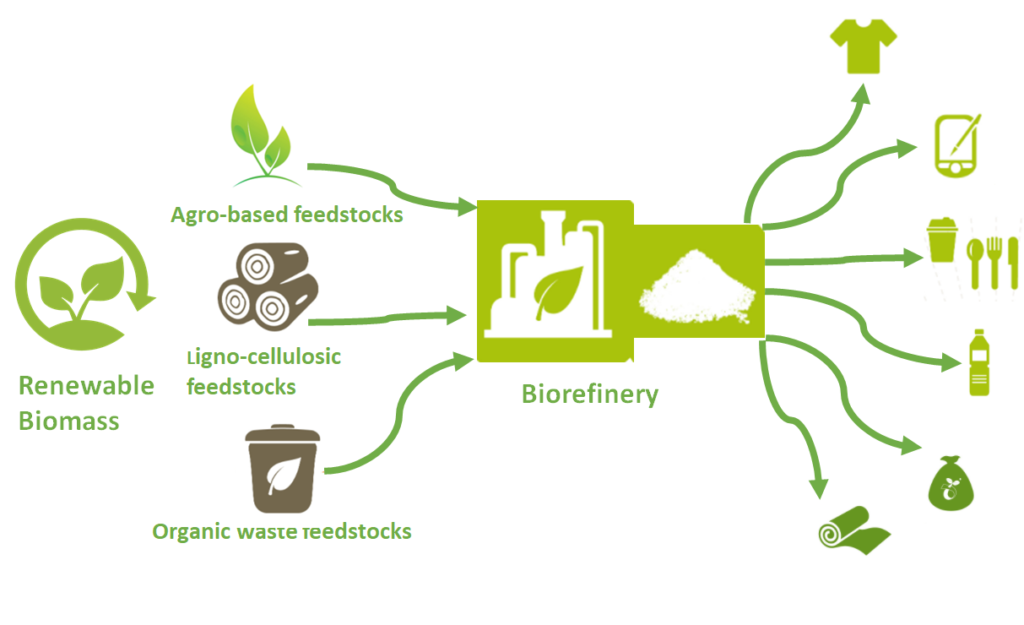

Biomass, as a source for bioplastics, origins from the following bio-based feedstocks: Agro-based feedstocks such as corn or sugar-cane, ligno-cellulosic feedstocks consisting of plants that can’t be used for food or feed production or organic waste feedstocks.

Some might raise the concern that with bioplastics there will be a competition between food, feed and bioplastics. However this is not the case as currently only 0.02 % of the global agricultural area is used for the production of bioplastics, compared to 97 % of the area that is used for the production of food and feed. Even with increasing bioplastics demand this number will still be moderate. Besides that, the bioplastics industry aims to further develop plastics from non-food feedstock such as non-food crops or waste from food crops.

The potential to produce bioplastics from ligno-cellulosic feedstock is huge as every year, nature produces 2000 bio. tons of dead plants in form of cellulose and lignin – this is more than all plastics ever produced since 1950!

In fact, the very first plastic product was a billiard ball made from cellulose in 1860. Even the first Lego stones in 1949 were made out of cellulose. But also because of cheap oil at the time, we simply ignored cellulose and biomass as a sustainable source for bioplastic materials.

According to the Ellen MacArthur Foundation a circular economy is “restorative and regenerative by design, which aims to keep products, components and materials at their highest utility and value at all times, distinguishing between technical and biological cycles”. With this definition in mind, bioplastics fit into this new economic concept as they help to break away from the linear economy characterized by “make, use, dispose” in favour of a more circular model based on “make, use, reuse, recycle”. Bioplastics are a perfect illustration of circularity as they use renewable, local raw materials to make more sustainable everyday products.